Discover Resources by Tags: solid

| Up a level |

Number of items: 10.

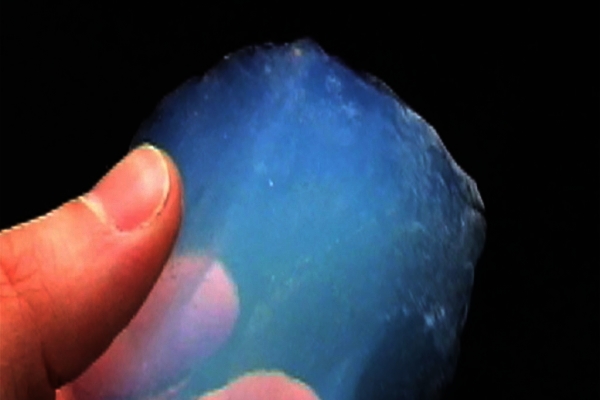

Aerogel

Shared with the World by Dr Zoe Laughlin

This is a rare sample of silica aerogel which is essentially a glass foam whose nano-structure contains up to 99.8% air, making it the world's lightest solid. It was made by Steve M. Jones, NASA Jet Propulsion Laboratory as part of the Stardust research project, which involved sending a spacecraft containing a large piece of aerogel on a close approach to the comet Wild 2 in order to collect space-dust. What made aerogel ideal for the mission was that, this ultra fine foam can gradually decelerate and capture dust particles in pristine condition. The process of then sifting through the aerogel, micron by micron, to identify and collect the space-dust was the world’s largest collaborative microscopy activity. The material appears to be much more invisible than glass despite being less transparent for there is no hint of reflection on its surfaces, giving it the appearance of not being fully solid. Its azure colour is not due to any pigmentation, but is caused by the same phenomenon that gives colour to our Earth's atmosphere, namely Raleigh scattering of light. In other words, it is blue for the same reasons that the sky is blue. Explore aerogel on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/aerogel.

Shared with the World by Dr Zoe Laughlin

Aluminium nitride wafer

Shared with the World by Dr Zoe Laughlin

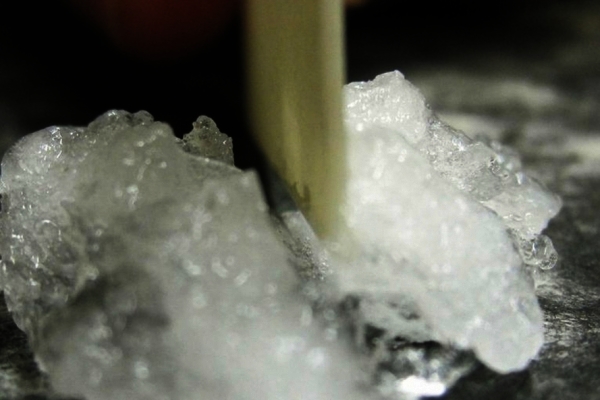

This thin fragile tile of ceramic material conducts the heat from your hand efficiently enough to cut through ice as if it were butter. Heat generated by the fingers is gathered from the two sides of the tile and conducted towards its edges, meaning that when an edge is placed against ice, the concentrated body heat melts the ice away. It is the speed of the conduction of heat that marks this ceramic out as a high performance material. If you hold it carefully between thumb and forefinger and then touch the edge onto you lip you will feel the rapid conduction of heat. Although the existence of this substance has been known of since 1862, it was not developed as a commercial product until the 1980s when its potential for use in electronics was recognised. Even then, early versions of this material were inconsistent. Although its performance has been greatly improved by technologists, its uses have thus far been fairly limited, largely to electronic and military applications, perhaps as a result of its high cost. Explore aluminium nitride wafer on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/aluminium-nitride-wafer.

Shared with the World by Dr Zoe Laughlin

Fibrous stainless steel

Shared with the World by Dr Zoe Laughlin

These super fine wisps of grey fluff are in fact tiny filaments of stainless steel. Each strand is around a 10th of the thickness of a human hair and make for form of steel like no other – one that is soft and able to be spun into yarns and woven into cloth. If you hold a magnet against the fibres you can see each little hair rise and fall. It still has the weight of steel and is for some a skin irritant as the super fine fibres can tickle. The fibres can be combined with other materials to produce a variety of effects like embedded conductivity and structural reinforcement. Explore fibrous stainless steel on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/fibrous-stainless-steel.

Shared with the World by Dr Zoe Laughlin

HDPE plastic waste

Shared with the World by Dr Zoe Laughlin

This slightly green tinted blob is a sample of extruded high-density polyethylene (HDPE) that is produced during the recycling process. HDPE is a type of polymer that is now commonly recycled and is used predominantly in the making of plastic bottles. Bottles arrive at the recycling plant and are passed through a giant shredder that chops them up to produce flakes of plastic. The flakes are then passed through a colour sorter to separate out dyed and non-dyed plastics. The white flakes are then heated to temperatures of over 200°C, which turns them into a molten form and eliminates any contamination. The molten plastic is then extruded, filtered, cut into small pellets, and cooled. These pellets are then sold on to make new food-containers and bottles of various recycled content (commonly between 25% and 50%). It is during this final extrusion process where waste material, such as this sample, is excreted out of the extrusion machine, spilling out onto the factory floor. These blobs of plastic, initially very warm to the touch, are collected and sold on for use within non-food safe grade recycled products. The reason that this blob has a slightly green colour to it is that occasionally a coloured flake makes it through into the white flakes pile. The most common colour of plastic is green, so the resultant white can often take on a slight green tinge. In order to reduce the greening effect of the white recycled plastic, the amount of green dye in British semi-skinned milk bottle lids has now been reduced. Explore HDPE plastic waste on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/hdpe-plastic-waste.

Shared with the World by Dr Zoe Laughlin

Natural rubber

Shared with the World by Dr Zoe Laughlin

When a rubber tree is tapped, a white liquid called latex bleeds from a fresh cut in the bark, the major constituent of which is a small carbon based molecule called isoprene. As the latex dries, the isoprene molecules begin to bind to one another and form long chains called polyisoprene. The long chains are intertwined and entangled, and they are quite happy to sit coiled up together due to an electrostatic attraction between them. When rubber is stretched, the individual polymer chains are stretched and line-up, and the order of the molecules is increased. This means that the entropy of the system is decreased and represents the force you feel in the rubber. When the rubber is released, all the chains pull back because this increases the entropy of the system. Explore natural rubber on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/natural-rubber.

Shared with the World by Dr Zoe Laughlin

Ridged aluminium honeycomb

Shared with the World by Dr Zoe Laughlin

Aluminium honeycomb structures can take many different forms – from regular hexagons, to partially compressed diamonds, to elongated, reinforced shapes. Mimicking the geometry of natural honeycomb, these widely varied structures all have one common feature - an array of hollow cells between two thin vertical walls. The combination of strong side panels with light-weight honeycomb core, commonly referred to as sandwich construction, makes for a very solid form through the use of minimal material. With a high strength-to-weight ratio and minimal density honeycomb structures exhibit structural integrity as well as insulative qualities. By increasing the depth, such as this sample, one can increase structural strength along the shape’s Y plane, but if compressed along the X plane this shape will easily deform due to its thin walls. Aluminium honeycomb is widely used throughout aerospace applications (including aircraft and rockets), as well as within architectural applications. But it can also be found in everyday products like packaging material and cardboard. Explore ridged aluminium honeycomb on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/ridged-aluminium-honeycomb.

Shared with the World by Dr Zoe Laughlin

Self-healing concrete

Shared with the World by Dr Zoe Laughlin

In the future we may be surrounded by concrete structures, which are able to self-heal cracks in their structure, with special bacteria doing the job for us. Tiny cracks in concrete do not necessarily affect structural integrity in the short term, but they do allow water and other chemicals to seep into the structure, which may cause big problems over time. Self-healing concrete has dormant bacteria and a food source (starch) embedded in the concrete. When a crack appears in the concrete, water seeps in and reactivates the bacteria. After they awaken, the bacteria eat their packed lunch and then conveniently excrete calcite, which heals the crack. The bacteria can survive dormant in the material for 50 years. Explore self-healing concrete on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/self-healing-concrete.

Shared with the World by Dr Zoe Laughlin

Shape memory actuator

Shared with the World by Dr Zoe Laughlin

This metallic wire shaped in a form of a spring is made of a special alloy of nickel and titanium (commonly termed a shape memory alloy) that is able to contract 4% or more when heated and then return to its original shape when cooling. This material’s ability to contract upon heating makes it useful in mechanical devices where heat, which is usually precisely delivered through an electric current, is used to generate some kind of motion. Shape memory actuators (SMA) are found in a wide variety of applications, from medical devices (portable insulin pumps) to computers and vending machines. Explore shape memory actuators on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/shape-memory-actuator.

Shared with the World by Dr Zoe Laughlin

Ulexite

Shared with the World by Dr Zoe Laughlin

Ulexite is a naturally occurring mineral with an unusual optical property. The internal fibrous structure of the rock act as naturally occurring optical fibres, transmitting light along their lengths by internal reflection. When a piece of ulexite is cut perpendicular to the orientation of the fibres and polished, it will display an image of whatever surface is adjacent to its other side. This optical property is common for synthetic fibres, but not in minerals. This strange behaviour makes the surface of the rock appear like a screen with the image of what is beneath the rock, projected onto the surface, giving rise to the material’s nick name of ‘TV rock’. Explore ulexite on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/ulexite.

Shared with the World by Dr Zoe Laughlin

![[img]](https://open-education-repository.ucl.ac.uk//307/2.hassmallThumbnailVersion/264_Image3-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//307/1.hassmallThumbnailVersion/264_Image4-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//316/1.hassmallThumbnailVersion/95.main-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//317/1.hassmallThumbnailVersion/FibrousSteal_Main-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//315/1.hassmallThumbnailVersion/1170_Main-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//315/2.hassmallThumbnailVersion/1170_Detail-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//314/1.hassmallThumbnailVersion/971.main-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//314/2.hassmallThumbnailVersion/971.detail-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//318/1.hassmallThumbnailVersion/7wwa-jrf_KNL9cXhS80uX-jeOc4NX5XuEkOQ4zDn7KY-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//318/2.hassmallThumbnailVersion/AluminiumHoneycombMain-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//313/1.hassmallThumbnailVersion/060-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//313/2.hassmallThumbnailVersion/062-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//312/1.hassmallThumbnailVersion/209.mainnew-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//308/1.hassmallThumbnailVersion/501_Main-600x600.jpg)