Discover Resources by Tags: light weight

| Up a level |

Number of items: 3.

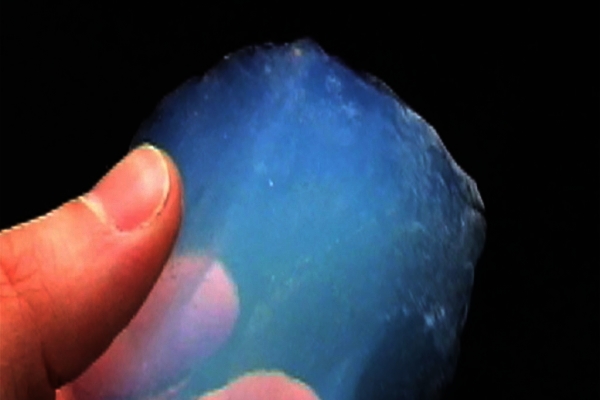

Aerogel

Shared with the World by Dr Zoe Laughlin

This is a rare sample of silica aerogel which is essentially a glass foam whose nano-structure contains up to 99.8% air, making it the world's lightest solid. It was made by Steve M. Jones, NASA Jet Propulsion Laboratory as part of the Stardust research project, which involved sending a spacecraft containing a large piece of aerogel on a close approach to the comet Wild 2 in order to collect space-dust. What made aerogel ideal for the mission was that, this ultra fine foam can gradually decelerate and capture dust particles in pristine condition. The process of then sifting through the aerogel, micron by micron, to identify and collect the space-dust was the world’s largest collaborative microscopy activity. The material appears to be much more invisible than glass despite being less transparent for there is no hint of reflection on its surfaces, giving it the appearance of not being fully solid. Its azure colour is not due to any pigmentation, but is caused by the same phenomenon that gives colour to our Earth's atmosphere, namely Raleigh scattering of light. In other words, it is blue for the same reasons that the sky is blue. Explore aerogel on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/aerogel.

Shared with the World by Dr Zoe Laughlin

Ridged aluminium honeycomb

Shared with the World by Dr Zoe Laughlin

Aluminium honeycomb structures can take many different forms – from regular hexagons, to partially compressed diamonds, to elongated, reinforced shapes. Mimicking the geometry of natural honeycomb, these widely varied structures all have one common feature - an array of hollow cells between two thin vertical walls. The combination of strong side panels with light-weight honeycomb core, commonly referred to as sandwich construction, makes for a very solid form through the use of minimal material. With a high strength-to-weight ratio and minimal density honeycomb structures exhibit structural integrity as well as insulative qualities. By increasing the depth, such as this sample, one can increase structural strength along the shape’s Y plane, but if compressed along the X plane this shape will easily deform due to its thin walls. Aluminium honeycomb is widely used throughout aerospace applications (including aircraft and rockets), as well as within architectural applications. But it can also be found in everyday products like packaging material and cardboard. Explore ridged aluminium honeycomb on the Institute of Making website: https://www.instituteofmaking.org.uk/materials-library/material/ridged-aluminium-honeycomb.

Shared with the World by Dr Zoe Laughlin

![[img]](https://open-education-repository.ucl.ac.uk//307/2.hassmallThumbnailVersion/264_Image3-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//307/1.hassmallThumbnailVersion/264_Image4-600x400.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//318/1.hassmallThumbnailVersion/7wwa-jrf_KNL9cXhS80uX-jeOc4NX5XuEkOQ4zDn7KY-600x600.jpg)

![[img]](https://open-education-repository.ucl.ac.uk//318/2.hassmallThumbnailVersion/AluminiumHoneycombMain-600x400.jpg)